The Z-Class Mixer

The Z-Class is the newest Zim-Mixer design. It features a digital control system that allows the mixer to be operated with a push of a button which constantly monitors all shaft speeds. This design also includes a manual override. This digital system is a custom designed control system for efficient performance and precise operation. The Telematics option allows constant monitoring of the unit along with office communication for instant billing. The Z-Class is ideal for specification contractors and retail companies that want to take their company operations to that next level.

The mixer and chassis specs are the same as the 400N1 Series models and can be found here.

Standard Equipment

Patented dual chain material feed system found only in Zim-Mixer equipment, which is the most accurate in the industry, longest lasting, self-cleaning, and has the ability to run any material individually.

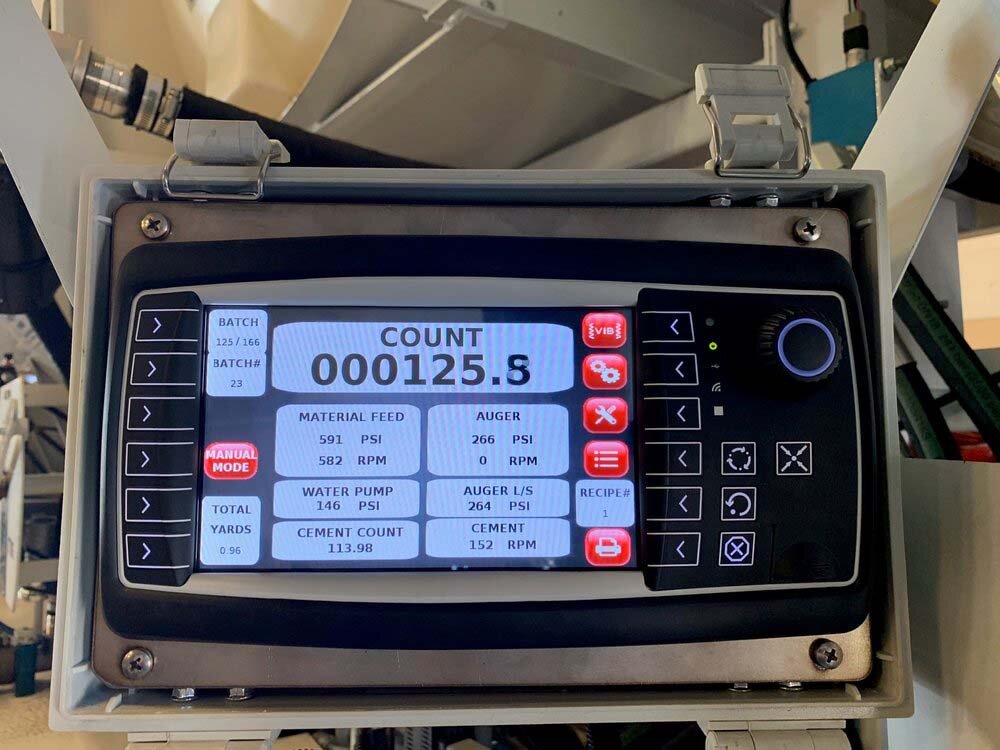

Z Class computer system provides superior accuracy and repeatability to all hydraulically driven components through a closed loop system while monitoring all system parameters.

Touch screen Digital control display monitor includes onboard warnings, diagnostics, troubleshooting, calibration and batch settings.

Manual override.

Aggregate bin with center divider.

Cement bin with power agitator which includes a patented chain feed system (unique only to the Zim-Mixer brand!) which is the longest lasting, most accurate in the industry, and is self-cleaning.

Polyethylene water tank.

Hydraulic water pump with a water solenoid valve which is quick acting for consistent mixing.

Digital water flow meter.

4-Section hydraulic pump provides an independent pump for each hydraulic circuit which gives the most consistent mixing and coolest running hydraulic system in the industry.

Hydraulic oil heat exchanger.

Automatic electrically controlled air vibrators with adjustable parameters.

Material counter.

9' mix auger with replaceable Ni-Hard wear pads.

Power auger lift and swing.

Manual telescopic chutes, which are mounted to the auger and require no attachment by the operator.

Unit painting which includes two coats of epoxy primer and two coats of industrial grade polyurethane paint.

Unit mounting on truck chassis, trailer, skid, etc...

Calibration yield box.

Operator training at customer location